Application scope

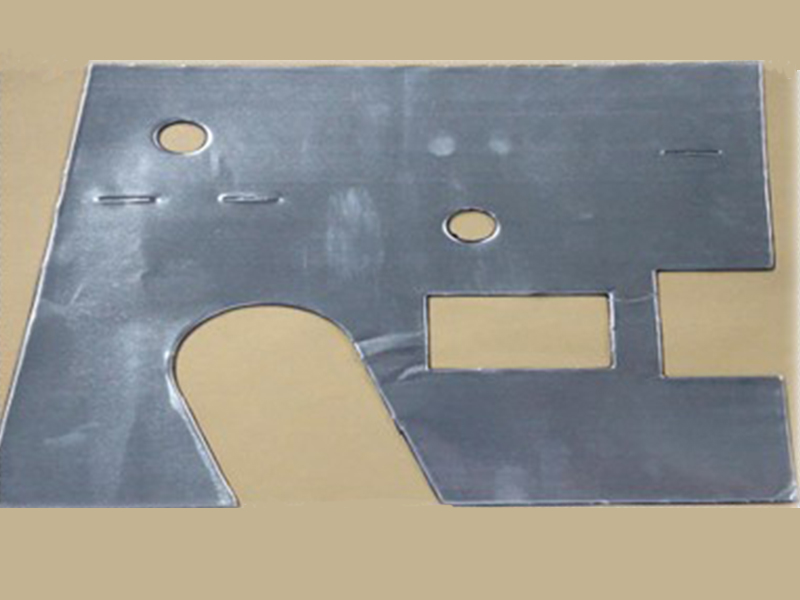

Steel plates for automobile bodies: CRS, surface galvanized or organic metal plates, processed aluminum plates, oily plates (up to 3g oil/m2), cured at the same time as electrophoretic paint to enhance the rigidity of the steel plate, reduce noise (trace amount), and reduce vibration role.

Peel off the release paper on the film, adhere it to the application site and compact it, and cure at high temperature of 160℃-210℃ for 30-60 minutes.

project | 数据 |

Exterior | The adhesive layer is in the form of a black sheet, backed by impregnated fiberglass cloth or aluminum foil. |

Thickness(mm) | 1.0-2.5 or according to customer requirements |

Density (g/cm) | 1.2-1.7 |

Non-volatile content (%) | >98 |

Initial bonding strength (N/25mm) | >5 |

Cure range (C, min) | 140-215°C,time20-30min. |

Under standard curing conditions | >5 |

Reinforcement multiple | Based on 2.5mm and 5mm displacement, and maximum load |

Applicable substrate | 0.6-0.8 mm thickness various cold-rolled steel plates, galvanized rice, aluminum plates |

|  |